How Modern Dust Control Technologies Are Transforming Hot Strip Rolling

A Smarter Way to Manage Dust in Rolling Mills

Hot strip rolling is a cornerstone of steelmaking, yet it brings with it a persistent challenge: oxide dust. This dust, released during the rolling of high‑carbon and high‑silicon steels, becomes especially prominent at the finishing stands where strip speeds are highest. Once airborne, it spreads quickly across the mill bay, affecting visibility, equipment reliability, strip surface quality and operator comfort.

As the global steel industry moves toward cleaner, safer and more efficient operations, dust control has emerged as a critical priority. With stricter environmental regulations and the growth of silicon steel production, steel plants worldwide are now investing in more advanced dust‑control solutions. This article explores how dust forms, why it creates operational challenges and how modern technologies, particularly atomised spray systems, are changing the way steel mills manage this issue.

Why Dust Forms in Hot Strip Mills

Oxide dust is generated when the surface scale breaks off the strip during rolling. The amount and type of dust vary depending on steel composition, rolling temperature and strip speed. The finishing stands (F4 to F6/F7) contribute the most, simply because the strip travels its fastest at this point. This rapid movement blows dust across long distances, affecting nearby equipment and working areas.

Plate mills and Steckel mills also face dust formation issues during reversing passes. Although process adjustments, speed management and thermal controls have been attempted over the years, these measures alone cannot create a dust‑free environment.

Operational Challenges Caused by Dust

Rolling mill dust does far more than settle on surfaces. It affects safety, maintenance routines and even the quality of the steel being produced.

- Reduced Visibility: Dust clouds significantly reduce visibility inside the mill bay, making it harder for operators to work safely, especially near moving machinery.

- High Cleaning Requirements: Dust settles on stands, sensors, cables and structural components, requiring frequent cleaning with high‑pressure water jets. This increases workload and planned downtime.

- Electrical Disruptions: Deposits on crane collectors and electrical leads can create insulation issues, short circuits and unexpected malfunctions, affecting mill reliability.

- Strip Surface Quality Issues: Dust resting on the strip surface can get rolled into it during subsequent passes. This results in oxide patches on both the strip and the rolls, affecting final product quality.

- Operator Health Concerns: Even with the use of personal protective equipment, operators often report breathing discomfort, eye irritation and fatigue due to airborne dust near generation points.

Why Effective Dust Control Matters

Modern steel plants depend on reliable, high‑quality output. Dust control supports this by:

- Reducing maintenance and improving equipment availability

Less dust means fewer shutdowns for cleaning, reduced wear and a longer lifespan for equipment. - Enhancing workplace safety and comfort

Cleaner air directly contributes to better visibility and healthier working conditions. - Supporting compliance with environmental standards

Governments and industry regulators worldwide now demand stricter emission controls.

Industry Approaches to Dust Control

Steelmakers have experimented with multiple dust‑control solutions, broadly classified into three categories: dry systems, wet systems and atomised spray systems. Each method has its own strengths and limitations.

Dry Dust Control Systems

Dry systems extract dust‑laden air using hoods, fans and synthetic bag filters. Although the concept is straightforward, these systems face several real‑world limitations:

- They must handle extremely hot, high‑volume air from the rolling zone.

- Fine dust from silicon steel is difficult to capture effectively.

- Installations at plants such as Baosteel and Chengde Jianlong indicated that filtered air still struggled to meet regulatory standards.

Because of these challenges, dry systems are often unable to support the higher dust volumes generated in advanced silicon steel operations.

Wet Dust Control Systems

Wet systems use a mixture of water and air to capture dust particles. This includes simple spray systems as well as wet electric dust collectors. Although more effective than dry systems in some cases, wet systems also have significant drawbacks:

- Water droplets are often too large to capture fine dust.

- The high dust output of silicon and stainless‑steel rolling reduces overall efficiency.

- Realistic dedusting efficiency remains only around 20–30 percent.

- Wet electric systems require frequent component replacements, raising maintenance costs.

Despite their widespread use in mills like Baosteel’s 1580 mm Hot Strip Mill, wet systems alone cannot meet today’s performance expectations.

Atomised Spray: A More Efficient Dust‑Control Method

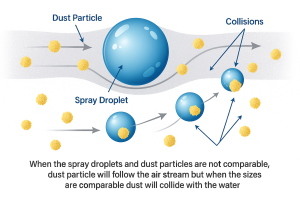

Atomised spray technology represents the most promising advancement in rolling mill dust control. Instead of large droplets, atomised spray creates a fine mist using high‑pressure nozzles. These small droplets travel longer distances, collide more easily with dust particles and bind to them effectively.

Why Atomised Spray Works Better

- Fine droplets remain airborne longer, allowing more collisions with dust.

- Once combined with dust, the heavier particles settle quickly.

- The system requires less maintenance than wet electric alternatives.

- It is cost‑effective and relatively simple to install.

Steel plants such as Xuanhua and Jinan Steel have reported strong performance using atomised spray systems, though results vary depending on mill layout and operating conditions.

How Atomised Spray Works

Atomised spray systems rely on the interaction between dust particles and fine water droplets. When water is forced through high‑pressure nozzles, it breaks into tiny droplets that float in the air rather than falling immediately. These droplets collide with airborne dust, attach to it and pull it downward.

Four parameters determine system performance:

Four parameters determine system performance:

- Dust particle size

- Water droplet size

- Spray pressure

- Nozzle diameter

Although the science is well‑studied in mining and coal applications, studies specific to hot strip rolling remain limited. Expanding this research could help plants further improve dust‑control efficiency.

Using Simulation to Improve Dust Control

Modern mills use advanced simulation to study how dust behaves between stands. These simulations:

- Track concentration changes using sensors above the stands

- Compare dust levels with and without atomised spray

- Help determine the best nozzle size and spray pressure

- Guide mill‑specific design improvements

The result is better dust suppression and improved product quality.

A Successful Industrial Application

Wuhan Iron and Steel, China, operates a 1580 mm Hot Rolling Mill with a capacity of 2.8 million tonnes per annum, producing both GO and NGO silicon steels. Atomised spray has delivered impressive results at this site.

Key operational settings include:

- Spray pressure: 0.5 MPa

- Nozzle diameter: 1.4 mm

- Water droplet size: 71.1 microns

- Dust particle size captured: 27 microns

- Dedusting efficiency achieved: 93.50 percent in the R2 Roughing Mill

These results highlight how a well‑designed atomised spray system can significantly improve dust control in demanding rolling environments.

Conclusion

Dust control in hot strip rolling has progressed from early dry and wet systems to today’s advanced atomised spray technologies. Although a completely dust‑free mill is not yet achievable, modern atomised spray systems significantly reduce dust levels and improve working conditions.

Data from BaoSteel and WISCO demonstrates that spray systems can achieve:

- 93.50 percent efficiency in Roughing Mills

- 86.69 percent efficiency in Finishing Mills

With improved design, simulation and precision engineering, atomised spray represents the most effective and practical dust‑control method available today.