Engineering Efficiency: The Role of Pelletisation in India’s Green Growth Story

The Changing Landscape of Ironmaking

In today’s iron-making world, pellet plants have evolved into vital hubs of efficiency, quality and sustainability. As steelmakers around the globe work to balance productivity with decarbonisation goals, pelletisation has become an essential enabler of this transition.

India’s iron and steel sector stands as one of the strongest pillars of the country’s industrial growth, supporting infrastructure and manufacturing at scale. However, it is also among the largest contributors to carbon emissions. To meet both national and global climate commitments, the sector must shift towards cleaner and more resource-efficient technologies.

Pelletisation has emerged as a critical process in this transition. It transforms iron ore fines,

traditionally considered unsuitable for direct use, into high-grade pellets that enhance furnace productivity, reduce coke consumption and lower emissions. By enabling the use of low-grade ores and improving yield, pelletisation plays a key role in optimising resources and reducing the environmental footprint of steelmaking.

The Role of Pelletisation in Resource Optimisation

India is the world’s second-largest producer of crude steel, and its demand continues to rise with rapid urbanisation and industrial expansion. However, the quality of domestic iron ore reserves is gradually declining, leading to an increased focus on beneficiation and pelletisation.

Pelletisation technology converts iron ore fines into uniform, high-quality pellets through stages such as grinding, filtration, balling and induration. These pellets offer consistent metallurgical performance, improved permeability in the blast furnace, and more stable operation in direct reduction iron (DRI) plants.

Beyond metallurgical advantages, pelletisation contributes significantly to resource efficiency. It enables the utilisation of ore fines that would otherwise be wasted, reduces the need for sintering (a process with higher emissions), and improves overall yield in ironmaking. Together, these benefits make pelletisation a cornerstone of sustainable steel production.

In India’s context, pelletisation aligns well with the national priorities of Atmanirbhar Bharat and sustainable industrialisation. It allows steel producers to improve productivity without proportionally increasing emissions, thereby supporting both economic and environmental goals.

Advancing Efficiency through Innovation

Pellet plants today are designed not only for capacity but for sustainability and efficiency. Modern facilities integrate energy recovery, process optimisation and automation to achieve higher performance with lower energy input.

Energy optimisation remains a central focus. Many plants are now using waste heat recovery systems to capture and reuse thermal energy from induration furnaces, reducing fuel consumption. Similarly, process gas recovery systems are being adopted to minimise energy loss and improve overall plant efficiency.

Digitalisation is transforming plant operations. The adoption of digital twins, advanced analytics and AI-driven process control allows real-time monitoring of critical parameters. Predictive maintenance systems help identify issues before they cause downtime, improving reliability and equipment life.

Automation has also enhanced precision and consistency in pellet quality. Variable frequency drives (VFDs), automated lubrication systems and advanced material handling solutions ensure smooth and efficient operation. These technologies together enable better control, reduced operational costs and improved energy efficiency.

Towards Responsible Water and Waste Management

Sustainability in pelletisation extends beyond energy efficiency. Modern pellet plants are adopting responsible water and waste management practices that contribute to a circular industrial ecosystem.

Water recycling and zero liquid discharge (ZLD) systems have become standard features in new and upgraded facilities. Efficient dust suppression and solid waste recycling systems further ensure that environmental compliance goes hand-in-hand with productivity.

Plants are also exploring innovative uses for by-products such as dust and sludge, integrating them back into the process chain. Such circular practices not only reduce environmental impact but also enhance operational resilience in regions facing resource constraints.

Case Insights: Learning from Operational Experience

In practice, the design of pellet plants must adapt to site-specific conditions, available raw materials and operational goals. The following examples illustrate how engineering innovation and operational insight combine to drive efficiency and sustainability.

Case I: Optimising Screening Systems in Europe

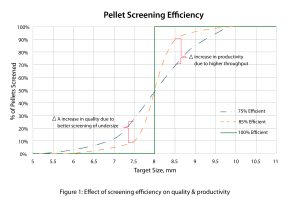

A 4.8 Mtpa pellet plant in Europe evaluated an upgrade from a single-deck to a multi-deck roller screen feeder to improve quality and throughput. Simulation studies showed that while multi-deck systems enhanced segregation and energy efficiency, they required significant space and investment. Considering the site layout and shutdown limitations, the plant opted for an upgraded single-deck roller screen with individual drives. This solution achieved better segregation and reliability without major structural changes, balancing performance with practicality.

Case II: Enhancing Efficiency in India

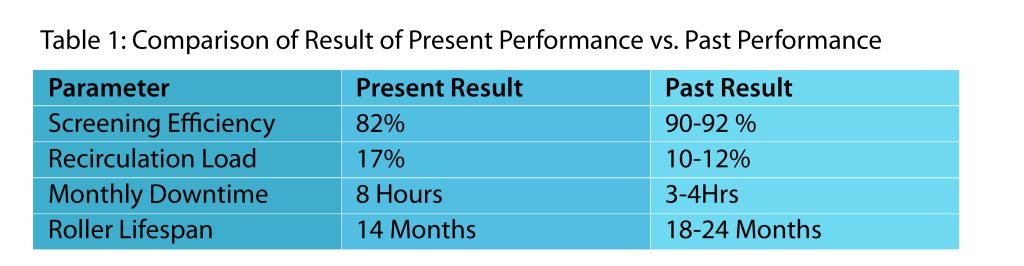

A 6 Mtpa dual-stream pellet plant in India faced high recycle loads and frequent downtimes due to worn-out rollers and misaligned screens. Detailed assessment and corrective actions such as replacing damaged rollers, introducing wear-resistant coatings and automating lubrication – helped restore efficiency to 95 percent. The plant reduced maintenance frequency, improved product uniformity and achieved better energy utilisation.

These cases demonstrate that optimal engineering solutions must be tailored to each plant’s specific conditions rather than relying on standardised designs. A data-driven approach, supported by field experience and simulation studies, ensures that every upgrade delivers tangible improvements in performance.

TCE’s Engineering Expertise in Pellet Plants

Tata Consulting Engineers (TCE) has been at the forefront of designing and delivering efficient, sustainable and future-ready pellet plants. With decades of multidisciplinary engineering expertise, TCE offers end-to-end support across the project lifecycle—from concept and feasibility to detailed engineering, construction management and commissioning.

The company’s integrated design approach focuses on optimising plant layouts, improving material flow and ensuring process efficiency. In both greenfield and brownfield projects, TCE’s teams leverage simulation tools, advanced modelling and cross-functional collaboration to ensure performance and reliability. TCE also supports clients in upgrading existing plants through debottlenecking, automation, and energy recovery systems. These efforts have consistently resulted in measurable gains in productivity and cost efficiency. The company’s work extends across India and overseas, contributing to projects that embody global best practices while addressing local environmental and operational challenges.

The Road Ahead

As India advances towards becoming a five trillion-dollar economy, its steel sector will play a central role in enabling infrastructure and industrial growth. Achieving this at scale while remaining sustainable will depend on widespread adoption of cleaner technologies and smarter engineering.

Pelletisation represents one of the most effective pathways towards greener steelmaking. It strengthens resource efficiency, reduces emissions and supports the long-term vision of a self-reliant, low-carbon India.

With its legacy of engineering excellence, TCE continues to be a trusted partner in this transformation. By integrating technology, sustainability and innovation, TCE is helping shape the future of ironmaking: one that is efficient, responsible and aligned with India’s green growth ambitions.